Dymondwood TipsTurners who attempt to drill Dymondwood with the same techniques they use on standard wood will often experience problems with overheating and cracked blanks. A few simple changes in technique will virtually eliminate problems with blowout and cracked blanks. Turners may also assume that Dymondwood needs the same finishing techniques that regular woods require. This is not true. Because of the phenolic resin, Dymondwood can be finished with sanding and polishing only.

Sawing When sawing Dymondwood, use fine tooth blades. I find 10 tpi bandsaw blades work well for this application. Saw the blank with the layers parallel to the table. If you saw with the layers perpendicular to the table, there is a good chance the last couple of layers will chip off near the end cut. This holds true for many types of wood. If you must cut perpendicular to the grain, use minimal pressure within the last 1/4" of the cut.

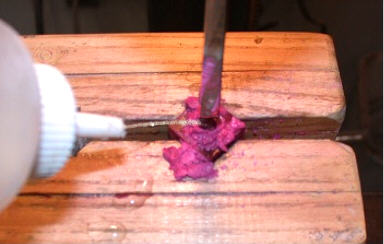

Drilling Dymondwood Use a drilling jig that supports the entire length of the blank. If you don't have a jig that fully supports the blank trying wrapping the blank in tape before drilling. Electrical tape works well. This technique will provide some support to the blank. If the blank does crack, the tape will hold chips in place, giving you the opportunity to repair with CA glue.

Drill Bits Every bit has its advantages and disadvantages. Brad Point bits are available in carbide; the big advantage is that you will spend less time sharpening drill bits. Pilot point bits work very well, but to my knowledge aren't available in carbide. I have seen parabolic recommended for Dymondwood, but I haven't tried them. I use a Carbide Brad Point. Always use very sharp tools. Don't try to get too deep with your cuts. Due to its hardness and brittleness, Dymondwood can chip or crack. Dymondwood is similar in drilling properties to Ebony.

Drilling Dymondwood Blanks Back out the drill bit frequently to clear chips and allow the blank to cool. If excessive heat and force are used, the Dymondwood blank can chip, crack or scorch. If chips are not cleared excessive side pressures may crack the blank. If you hear or feel a small "pop" during drilling, you've probably cracked the blank. This is usually a result of excessive drilling force or compacted chips in the drill flutes. See Gluing below. The easiest way to remove heat during drilling is to use water. Drilling speed can be increased if water is used as a coolant/lubricant. This is my preferred method for drilling Dymondwood. Water also works great for reducing airborne sawdust and increases the life of your drill bit.

If you create large amounts of steam (when using water), you know your speed is too high. All the energy being absorbed by the steam (heat of vaporization) would have been baking your blank and annealing your drill bit!

Sanding Wet sand with 120, 220, 320, 600, 1200 grit wet/dry sandpaper. For a finish that will pass the "Magnifying Glass Test" also wet sand with at least 4000, 8000, 12,000 grit Micro-Mesh™ Cushioned Abrasives.

Polishing Application of a plastic polish, such as Novus #2, will give you a high-gloss, luster finish. When properly sanded, the polish does its job in a few passes. For best results, clean and protect with Novus #1 as a final step.

Gluing Small nicks or chips can be repaired by filling with a fine sanding dust from the same color Dymondwood® and wetting with super thin CA glue. Hairline cracks repair easily with super thin CA. Allow the CA to wick into the crack for a few seconds and lightly clamp until dry.

Notes for just for Pen makers When using a blank end mill, use a cutter slightly smaller in diameter than the width of the blank. An oversized cutter is much more likely to chip or break the end of the blank. Many turners save time by plugging the tube ends before gluing. Some of the materials I have seen used are Play-Doh and potato. A non-greasy material is important. Standard pen blanks are intended for 7mm and 8mm(if you drill straight) holes. You'll need jumbo blanks for 10mm holes.

Dymondwood® Material properties: Caution: Various governmental agencies have identified wood dust as a health hazard. We always use appropriate safety equipment; we want to remind you to do the same. If you want to find information on wood dust a good place to start is the US government OSHA website.

|

The technique I use is to squirt water into the hole every few seconds while I

retract the drill bit. Use enough water so that chips come out as slurry. Do not let

the drill bit tip run dry. Drilling speed can be increased substantially by using

this technique. Because this technique is so effective, I would never go back to "dry

drilling."

The technique I use is to squirt water into the hole every few seconds while I

retract the drill bit. Use enough water so that chips come out as slurry. Do not let

the drill bit tip run dry. Drilling speed can be increased substantially by using

this technique. Because this technique is so effective, I would never go back to "dry

drilling."